Case study: MRO

MRO stands for Maintenance, Repair and Operations. It refers to products and tools used by companies to create a product, encompassing any item that is used in the production process but is not visible on the end product. Find out more about MRO here.

In order to deliver efficiency and cost control in this area, it’s key to get the operating model and process right. It’s possible to have the best rate card whilst bleeding cost if too many hours are being spent on jobs, or there is no control over scheduling, work taking place and invoices being signed off.

Here’s an example of how we can help:

About the client

Ebit worked with a manufacturing business with multiple sites of varying size across the UK. In terms of MRO, the client did not have a standardised process, or any price lists or parts lists. This meant that the same items were purchased from multiple suppliers across multiple sites at varying prices and via multiple engineers.

With more than 50 suppliers for MRO, just the top 5 represented 80% of spend. There were more than 4000 purchase orders raised per year.

Project overview

Ebit engaged with suppliers and provided an RFI overview which included the following categories:

- Lubricants

- Production consumables

- Production tools

- Engineering tools

- Engineering consumables (fasteners, fixings, pipe fittings)

- Fluid power / pneumatic / hydraulic components

- Transmission (belts, pulleys, sprockets, bearings, seals)

- Filtration

- Knives / blades

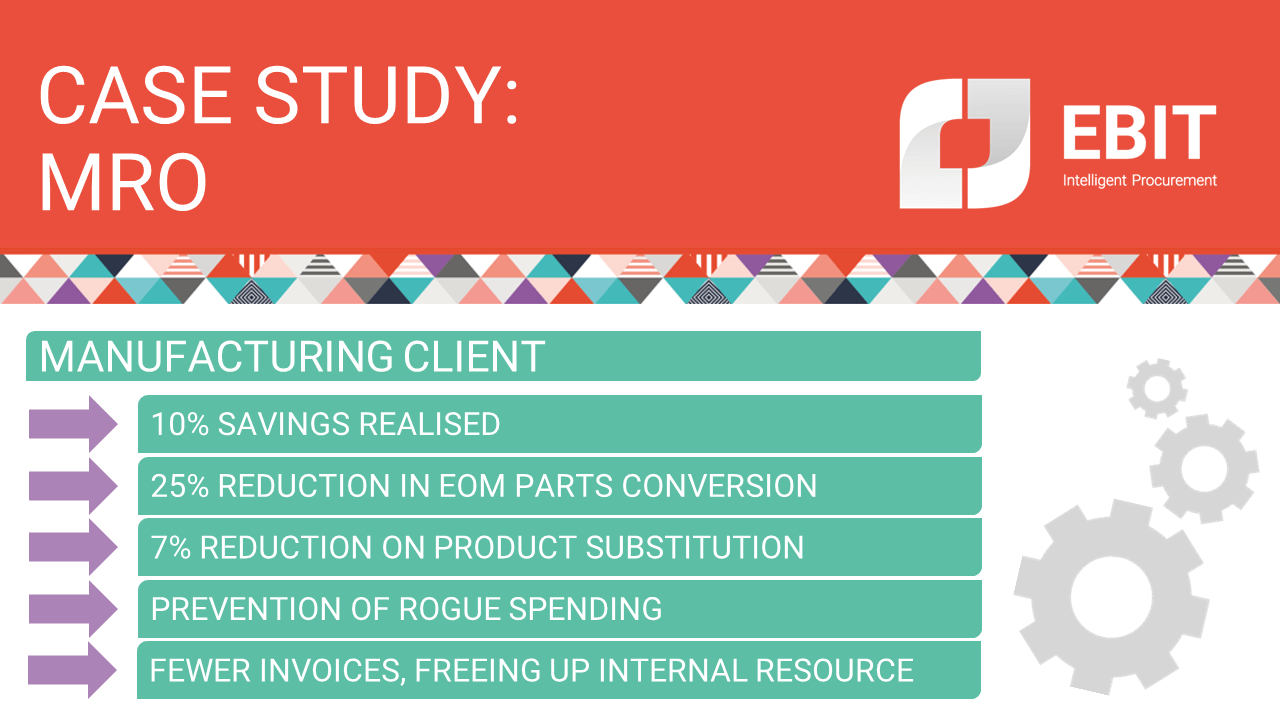

Results

Ebit delivered cost reduction as well as added value:

- 10% savings realised on purchasing and resultant operational efficiencies

- 25% reduction in EOM parts conversion

- 7% reduction on product substitution

- Single supplier selection to prevent rouge spending and ensure supplier quality levels

- A substantial reduction in invoice numbers, switching to EDI invoices direct to the client’s account system. This reduces AP and procurement involvement, saving time

- Energy audits introduced to ensure that scheduled maintenance schedules are correct and to check if machine settings need to be changed

MRO is just one area of indirect spend that we can help with. Contact us today to find out more about our procurement services and how they might be able to help your business.