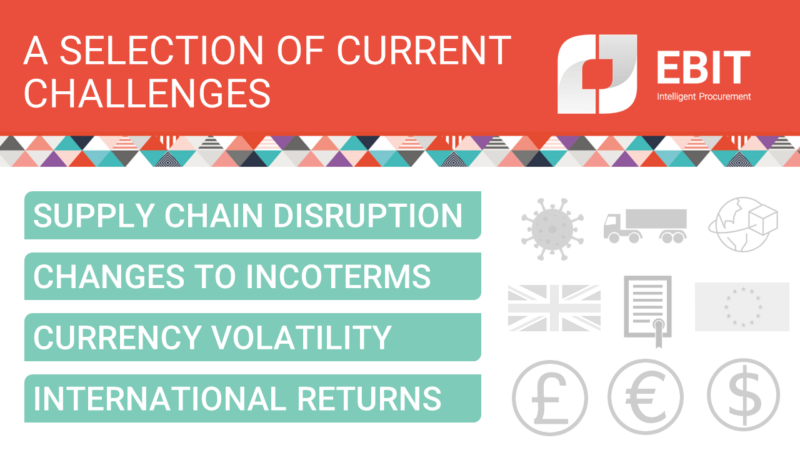

Hot topic: A selection of current challenges

In 2021, UK businesses are facing significant macro-economic disruption, with Brexit and COVID-19 having a huge impact. Procurement’s role in mitigating the effects of these challenges is more important than ever, as supply chains are tested and business costs scrutinised.

Brexit-related supply chain disruption

Although a trade deal is now in place with the EU, details of which services are covered by the deal have not yet been published. Whilst this is not a fundamental concern, it is important to closely monitor any upcoming changes from both a supplier and a client perspective.

Supply chain disruptions and delays are to be expected across all industry sectors as a result of the UK leaving the European Union. It is important to factor in potential tariff changes, port disruption, increased levels of checks, additional paperwork, and rerouting – all of which are issues that have also been exacerbated by COVID-19. As a result, delays and cost increases are likely.

Supply chain providers may need to pass on additional costs and surcharges in order to make the changes required to ensure that goods can pass through borders. These costs should be communicated and negotiated between parties to ensure fairness. Maintaining strong relationships with logistics partners should be a focus to keep communication open and up-front, and to mitigate potential delays.

Changes to International Commercial Terms (Incoterms)

Incoterms, a widely used terms of sale, are a set of 11 internationally recognised rules which define the responsibilities of sellers and buyers. Incoterms specify which party is responsible for paying for and managing the shipment of goods, any documentation, insurance, customs clearance, and other logistical activities which form part of a contract.

Incoterms will now be impacted by the Brexit deal, and contracts will need to be amended to reflect this. It is crucial to understand the flow of goods and services and relevant payments – not considering changes to these may result in a negative commercial impact.

Currency volatility

If Sterling drops in value, the cost of imports will increase. Currency volatility makes import cost changes difficult to accurately predict. If a business is exposed to a drop in the value of Sterling it may be worth considering whether it is possible to build up stocks of imported goods and products in the UK in order to reduce uncertainty.

International returns

Retailers with international customers need to consider whether they have an international returns solution in place, or if it is the customer’s responsibility to arrange their own return of goods. If the latter, logistics teams may face a potentially huge uplift in time, effort, and cost as it will be difficult to draw duties back on EU returns. The combined cost of this could stretch into the £millions.

However, setting up a returns portal with a reputable provider means that they will handle the consolidation and manifests of international returns, ensuring a smooth returns process for your customer but also enabling you to claim duties back from the manifests provided.

If you are wondering how to best manage these, and other procurement challenges of 2021, we would be happy to help. Contact us to find out more.